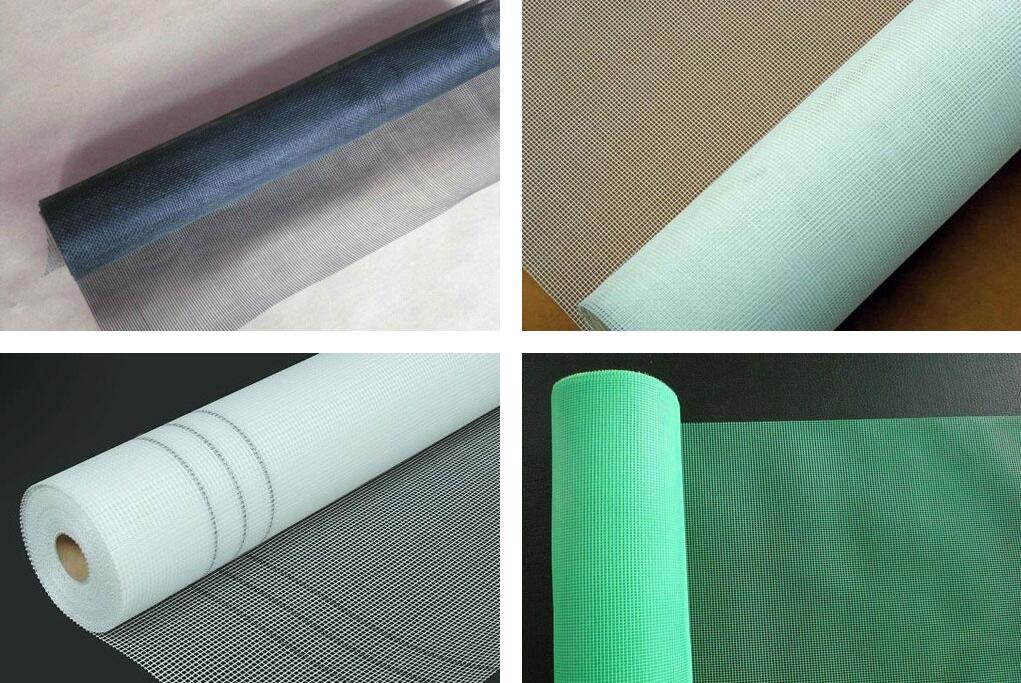

Fiberglass Screen Specifications

Fiberglass screen material is typically available in 100 foot rolls in varying widths, from 18 inches to 120 inches wide. Aluminum screen material is available in 100 foot rolls except the range of available widths is less than for the more commonly used fiberglass. The fineness of a screen mesh is measured in wires per inch on the warp (length) and the weft or filler (width). An 18 × 14 mesh has become standard; 16 × 16 was formerly common and other common sizes are 18 × 18 and 20 × 20.

Fiberglass solar screens provide over 75% of UV protection, by using thicker strands and a closer mesh than regular 18 × 14 fiberglass window screening. There is some reduction in visibility, but this can be advantageous, since Solar Screens are difficult to see through from the outside, while easier to see through from the inside.

Finer meshes have been developed to prevent very small insects. The finer mesh screens are also used to prevent pollens and allergens from entering homes in order to control allergic reactions.

Fiberglass window screen installation

1.Remove the spline, a round strip of material that sits in a trench all around the screen frame. If necessary, use a screwdriver to pry the spline out. Set the spline aside, but do not discard it. If you are replacing an old screen in the same frame, remove and discard the old screen fabric.

2.Lay the new screen fabric flat over the frame so that it extends past the spline trench by at least 1/2 inch (preferably more) on all sides. Cut the fabric so that it extends no more than around 1 inch past the trench on all sides. Cut the corners off of the fabric at 45-degree angles so that the screen fabric covers the spline trench completely, but the corners of the frame extend past the fabric.

3.Push the screen fabric into the spline trench all around the frame using the convex-edged wheel of a spline roller. Gently stretch the screen fabric as you work so that the fabric is taut in the frame. Go around the entire frame several times, until the fabric is taut and pushed fully down into the trench.

4.Press the spline back into the trench over the screen fabric using the concave-edged wheel of the spline roller. Stretch the spline as you go so that it reaches all the way around the frame; leave as little gap between the spline's ends as possible. Go around the entire frame two or three times until the spline is fully pushed down into the trench.

5.Hold the frame vertically and inspect it to make sure the screen fabric is completely taut within, there are no gaps where the screen did not reach the trench and that the fabric is not so taut as to warp the screen frame. If any of these are the case, remove the spline and start again at step 2.